High quality vent silencers manufactured by EI Williams are used in high pressure vents, safety relief valve outlets, steam vents, purge outlets, and system blow downs.

A vent silencer or a blow off silencer is a device used to reduce unwanted noise created by gas or steam flow in a pipeline discharging directly into the atmosphere. This noise can be generated due to the high velocity flow through the valve and turbulence created around any obstacle in the line that suddenly restricts or changes the direction of flow such as valve or an orifice.

A vent silencer or a blow off silencer is a device used to reduce unwanted noise created by gas or steam flow in a pipeline discharging directly into the atmosphere. This noise can be generated due to the high velocity flow through the valve and turbulence created around any obstacle in the line that suddenly restricts or changes the direction of flow such as valve or an orifice.

Vent silencers find wide applications in high pressure vents, steam vents, safety relief valve outlets, system blow downs and purge outlets etc. Vent and blow down noise is a function of upstream pressure and temperature, type of gas being vented, the valve size and type, plus the effect of down stream piping. Each vent silencer is designed to attenuate the noise level to the required sound pressure level criteria at a given distance from the silencer. This is the reason that vent and blow down silencers are seldom a catalogue selection. The details given here can be considered as a guideline. Contact our experienced engineers to recommend a silencer best suited for your application for vertical or horizontal installations.

In any steam or gas venting / blow off system, the primary release of noise energy occurs at the open stack exit. The blow off silencer is installed either within the stack or at the stack outlet to intercept this noise before it escapes into the environment. There are two fundamental noise reduction principles used in passive silencer design. Dissipative components (using sound absorbing material) provide balanced noise reduction over a broad frequency range. Reactive components, using resonant reflections within tuned chambers and passages, provide peak noise reduction in a more concentrated frequency band. The SV series vent silencers combines both dissipative and reactive technology in a highly efficient design.

Data Required To Select Vent Silencer

Application (Vent, Blow down, Relief)

Fluid Composition (Steam, Gas, Air)

Molecular Weight or Specific Gravity

Process conditions upstream of valve and units (lb/hr, SCFM, ACFM), Temperature Pressure (P 1)

Atmospheric pressure ( P a ) and temperature (T 2) if known.

Line size between valve and silencer

Line size from silencer discharge

Unsilenced octave band noise levels,

Attenuation required (silencer performance)

Allowable pressure drop

Sizing Of A Vent Silencer

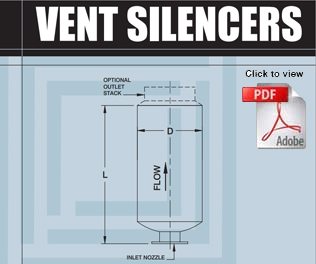

Typical examples of sizing a SV series vent silencer are shown here. The diameter of a silencer is a function of flow rate of the gas it can safely pass without eroding the acoustical packing or regenerating noise. The silencer length is a function of the degree of noise reduction to be achieved.

Sv Series Vent Silencers

The SV series vent silencers are recommended for reducing excessive noise caused by the discharge of high pressure gas, steam or air into the atmosphere. The silencers are of reactive / absorptive type design. The gas and noise enters the silencer through the single stage or multi stage diffuser where it is permitted to expand through many small holes into the expansion chamber. The design of diffuser and size of the expansion chamber provides a tuned reactive section. The diffuser also provides a frequency shift to higher frequencies which are best attenuated by the absorptive section.

The gas then passes through the absorptive section which consists of multiple perforated flow tubes surrounded by dense acoustical packing providing a broad range of attenuation in the mid to high frequency ranges. The standard construction is a rigid all welded carbon steel shell assembly, flow tube bundle and inlet / diffuser with acoustical packing of dense long strand fiberglass suitable for service temperatures indicated. Length of flow tubes and number of tube bundles is dependent on degree of silencing required. The silencer thickness includes 1/16" corrosion allowance and finished with rust inhibitive primer. The optional features include multiple inlets, special materials or finishes, mounting brackets and code requirements.

Design and Installation:

In standard gas or steam venting system, the release of noise energy generally occurs at the point of open stack exit. Hence, the vent silencer should be installed either at the stack outlet or within the stack to intercept and dissipate this noise before it can escape into the environment. In a passive silencer design created by EI Williams, we work on two important noise reduction principles – Dissipative components that provide balanced pulse and noise reduction over a wide frequency range, and Reactive components that use resonant reflections within the tuned passages and chambers, providing maximum noise reduction in a concentrated frequency band.

To learn more about EI Williams, call us at (905) 428-0950 or toll-free at 1-877-840-3347 or you can also email us at info@eiwilliams.com for further inquiries.